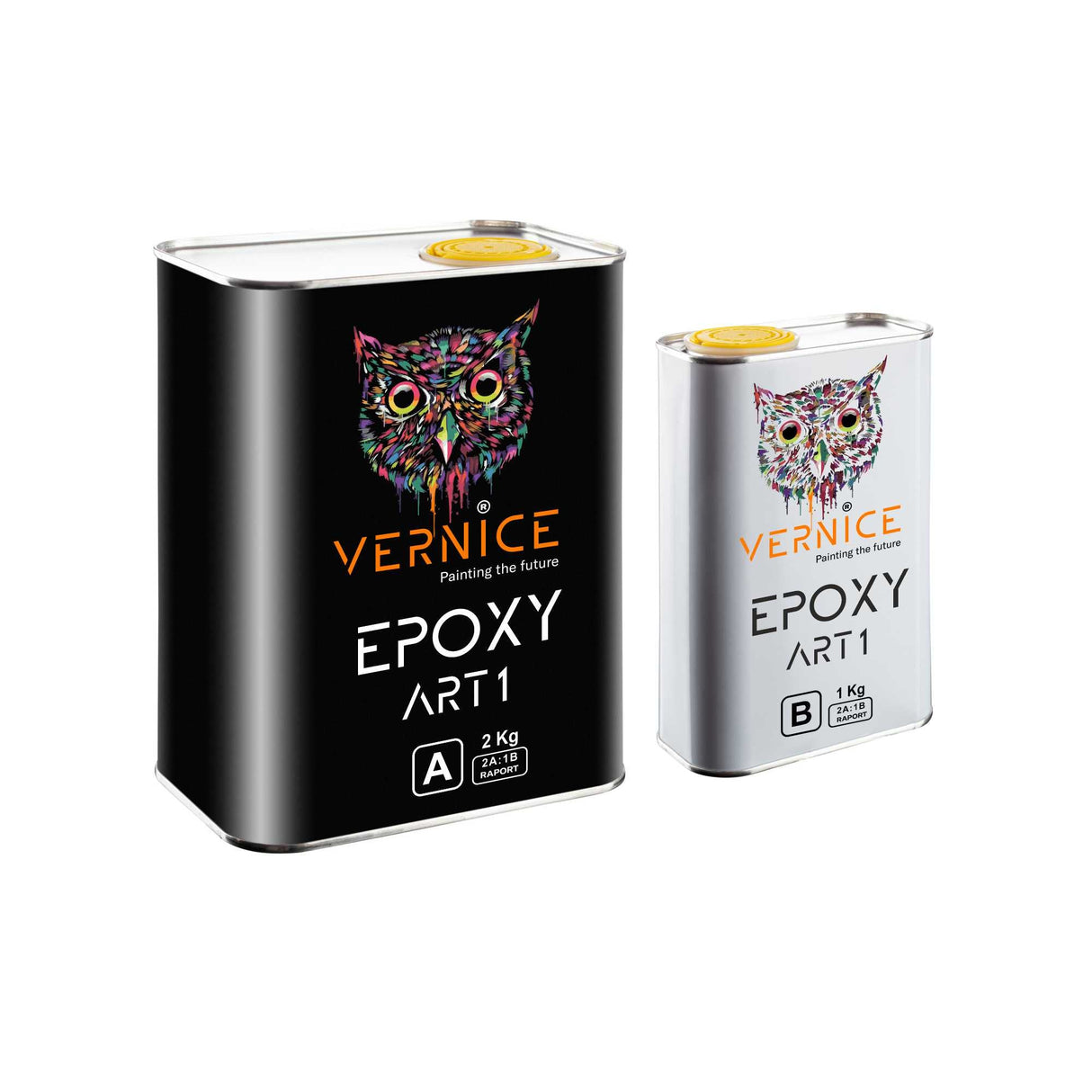

EPOXY ART 1cm 3kg

EPOXY ART 1cm 3kg is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and shipping

Delivery and shipping

Delivery by courier (standard)

The delivery fee is fixed: 19.90 lei anywhere in Romania , regardless of the order value, volume or weight of the package.

Showroom pickup

The personal pickup service from the Armorum showroom is available for the city of Sibiu, at the Vernice headquarters in Sibiu, Str. Calea surii Mici 68. Delivery to the showroom is free of charge.

If the products are not available in the showroom at the time you place your order, we will notify you by email or SMS when they are available for pickup. Once they arrive, the products are kept in the showroom for 4 days (starting from the day you receive the pickup notification).

For orders paid online, please have your ID with you when you pick up your products. For legal entities, a power of attorney from the company is also required.

Estimated delivery times are:

- 24-48h

- 2-4 days

- 7 days

These periods may vary depending on several factors, including:

- available stock

- product customization time (for customized products)

VERNICE

Specifications

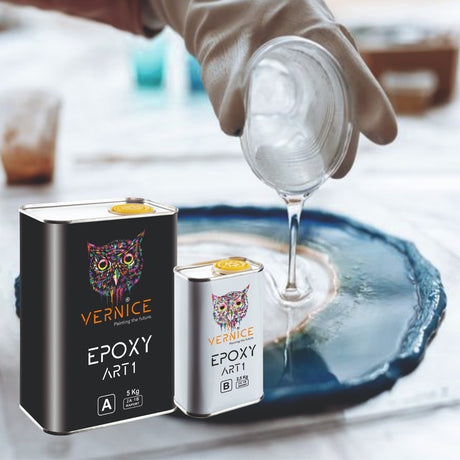

- Casting resin, up to 1 cm (per layer)

- Exceptional clarity (up to 98%)

- Easy removal of air bubbles

- Scratch resistant and can be sanded

- Effective drying time 24-36 hours

-

Working time (POT LIFE): 10 min

- Consumption: 1.6 kg/m2 / 1mm layer

Mixture ratio

- 2A:1B two parts resin A and one part activator B

Decorations

It can be combined with various metallic , monochrome , fluorescent or decorative glitter pigments .

Epoxy Art 1 is a two-component, transparent and super clear epoxy resin.

Various objects, decorative elements, jewelry, etc. can be made.

It is compatible with a wide range of substrates and casting molds,

molding together with wooden elements, decorative elements, etc.

It can be poured into wood in an unlimited number of layers with a maximum thickness of 1cm.

If successive layers are poured, it is recommendedthat DEGREASANT EPOXY is used before pouring another layer of epoxy resin on another already hardened layer.

Can also be poured into silicone or plastic molds

It is recommended that when pouring into wood, EPOXY WOOD SEALER be used to close the pores.

It is recommended to use DEMULANT EPOXY when casting in molds or formwork made of lemma or other porous materials to prevent adhesion and for easier demolding.

As a final layer of sealing and protection for the resin,EPOXY TOP LAYER is recommended.

Mixing

The mixing ratio of the components in VOLUME is 2A:1B (100A:50B)

The mixing ratio of the components by WEIGHT is 100A:45B

example of mixing by weight:

After combining the components, use a mixing spatula and use circular motions.

mixing very well for 3-4 minutes, the remaining resin not combined with the hardener will not harden.

IT IS RECOMMENDED TO MIX AS MUCH AS YOU THINK YOU CAN POUR IN A MAXIMUM INTERVAL OF 5-7 MIN.

pouring

The recommended working temperature is around 20 degrees, below 15°C is not recommended.

At ambient temperatures above 20°C the resin mixes, pours and hardens very well, however, working at higher temperatures there is a risk that the resin will react much faster (it will harden faster in the container in which it was mixed), leading to an exothermic reaction (overheating during hardening) Especially when casting in insulating molds without rapid heat release, such as wood, MDF, chipboard.

Removing remaining bubbles can be done with a heat gun, bubble off spray or flame.

Casting at temperatures well below 20 degrees can significantly affect

Consumption: 1.6 kg/m2 / 1mm layer

Payment and security

Payment methods

Your payment information is processed securely. We do not store your credit card details and do not have access to your credit card information.